MODELS: MaxiFlo Electromagnetic Flow Meter Series ME MODELS: MaxiFlo Electromagnetic Flow Meter Series ME

ME series Electromagnetic flowmeter is composed of sensor and converter. It works on Faraday's electromagnetic induction principle , used for the measuring of volumetric flow rate of liquids whose conductance is 5 μS/cm or bigger. It also can measure the corrosive liquids as strong acid, alkali etc., and two phase(liquid-solid)suspensions as mud, ore pulp, paper pulp, etc. It is widely applied in the field of petroleum, chemical industry, metallurgy, textile, papermaking, environmental protection, food and municipal administration, irrigation project, river dredge etc.

Features

- Becuase there's no bluff measurement elements, there's minimal pressure loss

- Proper selection of eletrode and lining materials can prevent attacks from aggressive liquids, corrossion, wear, etc.

- Measurement result has no relation with physical parameters of the fluid such as pressure, temperature, density, viscosity, conductivity, etc. Also, it is not affected by operating conditions, therefore, the accuracy is high and reliable.

- 2-line LCD displaying instantaneous and total flow rates, while showing operating status, parameters, measurement unit, etc..

- Wide turndown ratio of at least 30:1

- Various outputs including HART protocol, capability for communication with PC and network, etc.)

Performance Curve

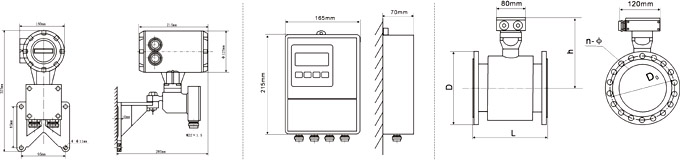

Dimensions

Integral Type

Separate Type

All the meters are calibrated accurately before shipment and shipped with test and calibration report to ensure the accuracy of the meter.

As standard, the meters are delivered with 1 year of warranty.

INSTALLATION GUIDE

- The display/transmitter can be installed either as part of the meter assembly or as a separate device located remotely.

- For the remote model, the remote distance can be as large as 30m but this can be extended to several kilometers if desired by using a special transmitter.

- The medium should have the minimum required conductivity of 5μS/cm.

- The installation location should allow enough straight pipe sections of 5D upstream and 2D downstream of the meter. And it is desirable that the medium flows from bottom to top.

- To ensure the accurate measurement of flow, the pipe should always be full.

- No excessive heat(such as by welding) should be applied to the meter.

- The electrodes should be aligned horizontally to eliminate or minimize the effects of air pockets and sediments.

SPECIFICATIONS

PIPE SIZES DN15 ~ DN2200

FLOW VELOCITY 0.3 ~ 12 m/s

MINIMUM CONDUCTIVITY OF THE FLUID 5μS/cm

ACCURACY ±0.5 ~ 1% of rate

OPERATING TEMPERATURE

Ambient: -10 ~ 50°C

Medium: <65℃(Hard Rubber Liner)

<120℃(PTFE Liner)

<180℃(Only available for Separate Type)

OPERATING PRESSURE

DN10 ~ DN80 : <4 MPa

DN100 ~ DN150: <1.6 MPa

DN200 ~ DN 1000 : <1.0 MPa

DISPLAY 2 X 20 alphanumeric back light LCD

POWER SUPPLY 220VAC, 50Hz(90~245VAC, 50Hz)

24VDC(20~36VDC)

POWER CONSUMPTION 6.5W

ENCLOSURE IP65 Standard (IP67 or IP68 available)

ELECTRODE MATERIALS: 316L, Hastelloy-C, Hastelloy-B, Ti, Ta

LINER MATERIALS: Hard Rubber(Polychloroprene), Teflon(PTFE), PVC

OUTPUT 4-20mA, Frequency, Relay, RS-485, HART protocol

|