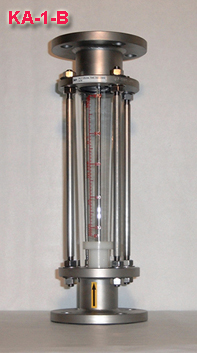

MODELS: KA, KB and KCA MODELS: KA, KB and KCA

|

Model Description

- KA: Glass tube rotameter with guide rod(Tapered tube)

- KB: Glass tube rotameter without guide rod(Tapered tube)

- KCA: Orifice + Rotameter combination meter(Non-tapered tube)

Features

- No need for straight pipe secteion upstream

- High accuracy, repeatability and linearity

- Can be used for liquid, gas and steam

- Low cost compared to other types

- Rib-guided metering tubes facilitate stable and accurate readings

- Ease of installation and replacement

- High pressure compatibility

- Hight temperature environment(Pyrex Glass)

- Chemical compatibility

- Wide selection of connection types(Flange, PT, NPT, ANSI, JIS, etc.)

- Wide selection of materials(306 SS, 316 SS, Metal, etc.)

- Wide choice of options(Control valve, strainer, digital ouput, etc.)

- High accuracy, repeatability and linearity

|

Owing to their simplicity, low-cost but high-reliability nature, these meters have found applications in a wide variety of industries including but not limited to paper/fiber, steel, petrochemical, food/beverage, air-conditioning, water treatment, chemical, etc. industries. Even with the rapid growth of new technology meters such as ultrasonic, electromagnetic and Coriolis meters, this type is still one of our steady sellers.

All the meters are calibrated accurately before shipment and shipped with test and calibration report to ensure the accuracy of the meter. The scales are inscribed with easily visible marking and can use the unit of the customers choice(index, percentage, actual flow(cm3/h, SCFM, etc.))

Meters that exceed the standard flow ranges can also be manufactured.

As standard, the meters are delivered with 1 year of warranty.

INSTALLATION GUIDE

- In normal cases, no straight run upstream is not required because the meter is not affected by the flow profile. But when there's pipe bend or control valve upstream, at least 1 length of the meter should be secured upstream to avoid higher reading than actual flow.

- When a valve is installed close to the inlet of the meter, the float can be unstable and unable to indicate the flow accurately. Therefore, for liquids, the valve should be installed downstream of the meter and for gases, because they are compressible, the valve can be installed either downstream or upstream as long as the pressure can be maintained stable. But this doesn't apply to the valves attached to the meters by us because the flow is calibrated with the valve.

- Because the meter relies on the gravity of the float for measuring the flow, it is critical to install the meter vertically within 1º tolerance.

- Places where there's vibrations should be avoided

- The piping should be securely fastened in order not to apply stress to the meter.

- It is recommended to have by-pass pipe for recalibration or replacement works.

SPECIFICATIONS

STANDARD ACCURACY ±2% FS

TURNDOWN RATIO 10:1

MAXIMUM OPERATING PRESSURE 10 KgF/cm2 G

MAXIMUM OPERATING TEMPERATURE 120°C

MATERIALS OF CONSTRUCTION

FLOW TUBES Pyrex® glass

FLOATS 304, 316 stainless steel, PVC, Teflon, etc.

BODY 41, 304, 316, 316L stainless steel, sanitary, etc.

PACKING N.B.R, PTFE, etc.

CONNECTIONS JIS, ANSI, PT, NPT, etc.

MODEL SAMPLES

|