4530

Series 4530

Series

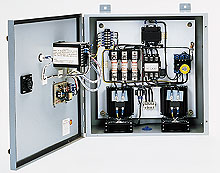

SCR

Temperature/Power Control Panels. Pre-wired,

Ready to Install, Zero-Crossover Fired, Three-Phase,

Two-Leg, NEMA-4 & NEMA-12 Enclosures Available.

Pre-Wired,

Ready to Install; Zero-Crossover Fired; 3-Phase,

2-Leg; NEMA-12 and NEMA-4 Enclosures Available.

|

|

|

Features:

The

4530 Mini SCR Panel Series is an economical,

convenient solution to mid-range SCR power control

requirements, eliminating the need to select,

collect and assemble separate components. The

preconfigured panels are ready to install, requiring

only power supply, load and sensor wiring. Their

compact packaging makes them easy to mount,

even in limited spaces. NEMA-4 Enclosures

are intended for indoor or outdoor use primarily

to provide a degree of protection against windblown

dust and rain, splashing water and hose-directed

water. NEMA-12 Enclosures are intended

for indoor use primarily to provide a degree

of protection against dust, falling dirt, and

dripping non-corrosive liquids.

|

6100

Series 6100

Series

1/16

DIN Proportional or On-Off Temperature Controllers

with Dedicated Inputs & Ranges. Models:

6102, 6103 or 6132H .

1/16

DIN Panel Cutout - Model 6102; 11-Pin Connector

- Model 6102; Thermocouple and RTD Models

- Model 6102 and 6103;Time Proportional Temperature

Control - Model 6102 and 6103;10 AMP Capacity

- Model 6102 and 6103; 1/4" Terminal

Lugs - Model 6103

|

|

|

Features:

The

Model 6102 Temperature Controller is one of

lowest cost units with all the features of big

controllers. Packaged in a small size to save

you space and money, Model 6102 temperature

controllers plug into an unbreakable nylon socket

which can be mounted individually or snapped

onto the Model 6000-TRK mounting track. The

unbreakable nylon socket and mounting track

make installations in chassis, control panel

and O.E.M. applications fast and easy, using

a minimum of space.

The

Model 6103 Temperature Panel Mount Controller

with its small size is the logical choice for

use on today’s multi-zone extruding and molding

machines. It is available off-the-shelf in a

wide selection of thermocouple types and ranges.

A complete Terminal Accessories Kit (6100-ACC)

is included.

|

70

Series 70

Series

Audible

Alarm Annuciators - Models: 70A-1, 70A-2, 70A-3,

70A-4.

Model

70A Temperature Alarms are the latest development

in solid state sound production. When power

is applied, a piezoelectric transducer operates

as a solid state oscillator resulting in a loud,

audible alarm tone. Temperature Alarms

are designed to give years of trouble-free service.

There is no arcing or mechanical wear, and they

are rugged and easy to install. Only a 1 1/8"

diameter hole is required for mounting by removing

the front plastic nut, inserting unit and rethreading.

Units are easy to operate. Simply connect to

a temperature controller and 120 volt ac power

supply.

|

|

|

Humidity:

Model 70A Temperature Alarms will operate after

having been subjected to 95% relative humidity

at 40°C continuously for 100 hours. After

removal from high humidity, the unit should

be allowed to dry for a minimum of four hours

at room temperature before operation.

|

AR

Series AR

Series

Rugged

Bulb & Capillary Thermostats.

ARR

Series May Be Used to Control Refrigerating,

Ventilating, and Alarm Systems.

|

|

|

These

thermostats use sensitive bulbs that can be

used in confined locations. Styles 4 and 5 bulbs

are designed for inserting in drilled holes

in platens and dies or for direct immersion.

Sensors for air and pipeline heating applications

(style 9) can be coiled to inside radii as small

as 13 mm (1/2 inch).

|

CCD100

Series CCD100

Series

Compact,

Economical Non-Indicating Temperature Controllers

(used as a Remote Control Thermostat) Models:

CCD100N-(*), CCD101N-(*).

|

|

|

Applications:

The CCD Temperature Controller is

used as a remote control thermostat for individual

circuits requiring a weatherproof device.

The

CCD100N SPST Thermostat uses a temperature-sensitive

bi-metal disc in an epoxy-sealed housing. Upon

reaching the non-adjustable calibrated setpoint,

the disc activates a plunger, causing the heavy

duty switch contacts to open. The CCD100N is

normally used as an across-the-line switch,

but may be used to operate contactor coils and

other similar devices.

The

CCD101N is an SPDT Thermostat with the same

features as the CCD100N, except that it has

an additional pole which can be used to operate

external alarm devices or as a limit controller

in conjunction with other CCD Series thermostats.

|

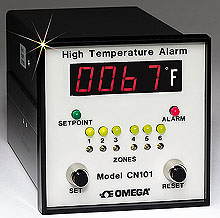

CN100

Series CN100

Series

1/4

DIN Temperature Six Channel Monitor with One

Alarm.

|

|

|

The

CN100 temperature monitors enable the operator

to continually monitor six thermocouple inputs

providing a high or low alarm. Each input channel

is independent, with individual setpoints. The

CN100 scans each channel, and in the event of

an alarm, scanning will halt, and the single

SPDT relay will change state; when the manual

reset button is depressed, scanning will resume,

and the relay returns to normal. CN102 low alarm

models also feature built-in cold start suppression,

which suspends low alarming until all six temperatures

have reached their setpoints.

|

CN1001 CN1001

1/8

DIN Digital Proportional On/Off Temperature

Controller.

|

|

|

The

CN1000 Series combines the features of a controller,

monitor and temperature limit alarm into one

easy-to-use digital meter for applications that

require maximum versatility. The CN1001TC is

selectable for J, K, T or J DIN thermocouple

input with 1° resolution. The CN1001RTD

is selectable for 2, 3, or 4-wire, 100 ohm Platinum

RTD inputs (alpha = 0.00385) with 0.1degree

resolution. Dual independent setpoints are available

and are programmable for proportional or ON/OFF

operation. The standard analog output is a retransmission

of the temperature input and can be sent to

a remote chart recorder, datalogger or data

acquisition system.

|

CN132

Series CN132

Series

1/32

DIN Autotune Temperature/Process Dual Setpoint

Controllers.

|

|

|

The

CN132 digital microcontrollers include all the

features of standard 1/4, 1/8 and 1/16 DIN microprocessor

controllers, in a very small package. The CN132

features advanced Autotune PID. Autotune teaches

the controller the main characteristics of the

process. Autotune learns by cycling the output

on and off. The results are measured and used

to calculate optimum PID values which are automatically

entered in the controller memory. Optimum cycle-time

is calculated by Autotune programs. The choice

of cycle-time is influenced by the external

switching device or load, e.g., contactor, SSR,

valve. Each control parameter also can be set

by the user through the front keypad. These

units include program security in a hidden level

for authorized personnel.

|

CN1501

Series CN1501

Series

1/8

DIN On-Off Temperature or Process Controllers

with 5 Ramp and Soak Programs plus 2 Timers

with Optional Outputs and Communications.

|

|

|

The

CN1501 indicator offers sophisticated microprocessor-based

temperature control with ramp and soak, in a

convenient 1/8 DIN (cutout) case. The CN1501

can store up to five ramp and soak profiles

in memory; each profile can have up to 10 ramp/soak

segments. The CN1501 uses ramped on-off control

to provide optimum temperature stability. The

CN1501 can display average rate of temperature

change per minute, as well as instantaneous

temperature. Low and high peaks are constantly

monitored, and can be displayed at the touch

of a key. Two programmable timers are also featured

(second timer is also used for On/Off control).These

timers can be used as timer or time/temperature

based alarms.

|

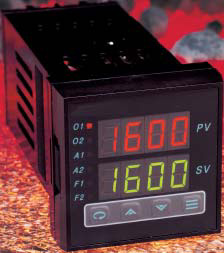

CN1504

& CN1507 Series CN1504

& CN1507 Series

1/8

DIN 4-Zone & 7-Zone Temperature/Process

Controllers with Ramp/Soak Capability.

|

|

|

The

CN1500 series is a compact unit that offers

the features of up to seven controllers in a

single 1/8 DIN enclosure. Careful design, high

functionality and compactness allow it to offer

the best cost/performance ratio of any controller

in its class. The input type for each zone is

selected independently. Scaling and offset allow

current and voltage signals to be converted

and displayed in engineering units. Temperature

can be displayed in Centigrade or Fahrenheit.

Each zone has its own ramp/soak profile with

up to 7 segments. ON/OFF as well as PID control

is offered for optimum process stability. Processes

that do not require tight control through complex

tuning of PID parameters can be run under simple

ON/OFF control. Each zone has its own set of

ON/OFF and PID parameters and each zone can

be programmed for heating or cooling. Setpoint

deviation, positive as well as negative, can

be viewed. Additional functions include min/max

reading for each zone, indefinite program hold,

automatic scanning and displaying of different

zones and three display modes (setpoint only,

process only or both setpoint and process).

Power, control, and process signal connections

are conveniently made with Euro-style plug-in

connectors. Each zone has a three-digit long

engineering label that can be programmed to

indicate the type of process being controlled,

e.g., °C or °F for temperature, PSI

for pressure, etc. Every controller’s output

status is indicated by LED’s. Channel-to-channel

scan time is also programmable.

|

CN1622

& CN1612 Series CN1622

& CN1612 Series

1/4

& 1/8 DIN Limitl Temperature/Process Limit

Controllers with Modular Outputs and Communications.

|

|

|

The

CN1612 and CN1622 are a new line of limit controllers

designed to provide a programmable safety cut

out and optional alarm for use in a wide variety

of applications with process controllers. The

CN1612 and CN1622 both provide a latched relay

output which is activated when process parameters

either exceed or fall below the desired value,

providing a fail safe shutoff which has to be

manually reset before the process can continue.

The instrument can be configured to be either

a high limit unit where the relay will de-energize

when the process variable is above the limit

setpoint, or a low limit where the relay will

drop out when the PV falls below the setpoint.

LED indication shows when limits have been exceeded

and when the relay is latched out. It offers

a full range of universal sensor input options,

versatile configuration and a front panel sealed

to NEMA-4/IP65 standards. The CN1612 and CN1622

both provide a valuable safety control element

in most applications and systems.

|

CN1A

Series CN1A

Series

1/16

DIN On-Off LCD Temperature Controllers with

Dual Outputs. Models: CN1A-TC, CN1A-RTD.

|

|

|

The

CN1A Series is a digital On/Off temperature

controller designed to provide the functionality

of general purpose PID controllers but at a

price suited to On/Off applications. The simple

programming with two front panel keys, uncluttered

LCD display, and uncomplicated control functions

and alarm programming have enabled the CN1A

to be widely used in a variety of applications.

To add a timer to your panel, the associated

PTC-1A is designed to combine a harmonized appearance

with simple-to-operate, flexible functions and

high reliability. The CN1A, when combined with

the PTC-1A complimentary timer is ideal for

frequent user-adjustable applications such as

hot foil printing, window sealing and environmental

ovens, which often require both temperature

and timing control.

|

CN2110

Series CN2110

Series

1/4

DIN Compact Temperature Controller

|

|

|

The

CN2110 Temperature Controller offers simple

setup, flexibility and control features in an

attractive, compact design that both OEMs and

users will find costeffective. The CN2110 is

housed in a rugged, plastic 1/4 DIN package

that only requires four inches behind the mounting

surface. Straightforward operation and easy-to-use

control features are major strengths of the

CN2110 controller.

Full

Feature Outputs: A total of six output types

further extend the applications flexibility

of the CN2110 controller: (1Amp relay; 20 Amp

Relay; 1 Amp Solid State Relay; 5 Amp Solid

State Relay; 10 Amp Solid State Relay; dc pulse,

SSR drive).

The

CN2110 features a variety of output modules

including High Current options of a 10 Amp Solid

State Relay or 20 amp mechanical relay. These

outputs can directly control many cartridge

or strip heaters, eliminating the need for a

remote contactor or solid state relay. For larger

three-phase loads, the CN2110 can drive a remote

device with the Pilot Duty Relay or Solid State

Relay Drive outputs. The optional Alarm Output

gives you a non-latching, normally deenergized,

5 Amp relay output for over or under temperature

protection of critical process temperatures.

Packaging

with the User in Mind

The

CN2110 features a NEMA 4X front panel with tactile

feedback push buttons. Large, bright LED’s provide

an easy-to-read interface at a distance.

Flexibility

& Simplicity

Outputs

are plug-in modules that are field replaceable.

The switchselectable control modes include On-Off

or Proportional-Integral (PI). Sensor type J,

K, RTD are also switch selectable. No programming

necessary.

Features

High-Current Switching

The

CN2110 features high current output switching

(relay and solid state relay), eliminating the

need for an external power switching device

and reducing installation cost. Single phase

loads up to 20 amps may be directly connected

to the CN2110, eliminating the need for a remote

contactor or solid state relay. The internal

relay option can switch up to 20 amps or the

internal solid state relay option can switch

up to 10 amps. The CN2110 automatically detects

the output type and adjusts the controllers

setting for optimal control.

Control

Modes

The

CN2110 provides precise, solid state proportion

control with automatic reset (PI) that will

control most heating applications. ON/OFF control

may be selected for applications where maximum

output life (load switching) is needed.

|

CN3101 CN3101

1/4

DIN Limit Temperature/Process Controllers with

Modular Communications Options.

|

|

|

The

CN3101 is a compact, fully programmable high

or low limit controller. It is UL listed and

has FM approval as a limit controller. With

user programmable inputs, outputs and high/low

limit features, it is adaptable to almost any

limit control application, and can easily be

reconfigured as needed. Sophisticated limit

control features include a total time over/under

setpoint display and peak (maximum or minimum)

process variable display. These valuable CN3101

features allow you to determine if process damage

has occurred, and they can help in analyzing

the cause if shutdown occurs.

|

CN3230 CN3230

Environmental

Test Chamber Controllers. 1/4 DIN Size and Dual

Temperature/Process Inputs.

Models:

CN3231 and CN3232.

|

|

|

CN3230

is a Dual Channel Environmental Test Chamber

Controller. Along with its expansive memory

and flexible programming capabilities, the CN3230

has the added features of two sensor inputs

and four control outputs. The two control channels

may both function as temperature control, or

channel #1 as temperature and channel #2 as

humidity, making the CN3230 the perfect choice

for environmental chamber, oven and furnace

applications requiring highly sophisticated

control. The humidity control algorithm accommodates

both transmitter and wet bulb temperature inputs.

The controller converts either input into a

relative humidity value, thus functioning as

a true humidity controller and requiring no

calculations or conversions by the operator.

16

ramp/soak programs, each having a separate standby

setpoint and 8 individually timed intervals,

give you a total of 128 intervals. Any interval

or sequence of intervals can be looped up to

255 times, and any of the 16 programs can be

linked to another program. The CN3230 features

nested program loops, allowing configuration

of complex process profiles that loop from any

interval in a program to any interval of the

other 15 programs.

8

event outputs per interval are possible. Each

controller is equipped with 4 SSR event outputs

as standard, and an additional 4 outputs are

available as an option. These event outputs

give the CN3230 added control power to turn

on conveyors, valves, fans, annunciators or

other remote devices. The 4 alarm settings may

be assigned to up to four of these solid state

relay outputs, and each alarm can be set up

as high, low or deviation alarms, normally energized

or normally de-energized.

Guaranteed

soak, automatic hold and separate PID control

parameters for all 4 control outputs. Two different

proportional band settings can be programmed

for each control channel (easily accommodating

applications where the gain of different processes

dictates significantly different PID control

parameters for precise control). When establishing

a program profile, simply select the proportional

band setting most appropriate for the process.

Remote

operation of ramp/soak programs allows you to

select from a remote contact closure: ·

START/CONTINUE; · HOLD; · STOP/RESET.

An

Optional 4-20 mA analog output (field changeable

to 1-5 Vdc) is available, in addition to the

4 standard SSR control outputs, and can be assigned

to represent any one of the four control outputs,

or the process variables or setpoints.

Programming

logically organized into 22 PAGES of like MENU

numbers, requiring only simple menu selections.

The result is a specific address for each and

every control adjustment or selection to be

made, quick and easy programming, and no confusion!

Programmed

information is protected by non-volatile memory

and 6 coded levels of security. In the event

of a power failure, the CN3230 will retain all

of the programmed parameters and program profiles.

The 6 security levels require codes to access

and change parameters, to prevent unauthorized

or accidental access to programming.

Simple

front panel pushbuttons and alphanumeric cues

make ramp/soak program operation and programming

easy. The dual 4-digit LED displays give constant

indication of channel #1 and channel #2 process

variables and setpoints, while alphanumeric

cues guide you through programming.

Optional

RS-232 and RS-422 Digital Communications is

available and can operate without a mainframe

or PC interface. By connecting a standard ASCII

data terminal or PC to the CN3230, you can select

or adjust any parameter that can be accessed

from the controller's front panel. Automatic

datalogging gives you a printout and/or display

of up to 11 different control parameters and

variables as often as every minute, or whatever

time interval chosen. If several controllers

are on a single line, the user can write multidrop

software, or use the software package, CN3200-SOFT.

|

CN3240 CN3240

1/4

DIN Independent Dual Channel Temperature Controller

with Timer, Ramp/Soak and Idle Functions. Communications

Option has RS-232/RS-422/RS-485 all in one.

|

|

|

CN3240

Series temperature controllers pack the sophistication

and flexibility of two microprocessor-based

controllers into one compact 1 /4 DIN package.

Two

Flexible Loops

Each

of the two independent control loops can be

field programmed:

Loop

#1 Loop #2

PID

Temp. Control PID Temp. Control

PID

Temp. Control Overtemp. Control

Alarm/Overtemp

Alarm/Overtemp

Two

sensor inputs (one per loop) can be field programmed

as J or K thermocouple or RTD. The control outputs

are 8 amp relays, field changeable to dc pulse.

The relay output can be used to directly drive

small heater loads. In addition, a third 10

Amp relay can be used for alarm control.

Timer

and Event Input Features

Incorporated

into the CN3240’s programmed control features

is a basic timer, configurable in hour/minute

increments. The CN3240 timer can be used to

enable the process at a preset time, or disable

the process after a specified amount of time,

avoiding the additional expense, space requirements

and installation costs of a separate timer.

Most importantly, the CN3240 timer assures you

of total compatibility with the CN3240 process

controller functions, requiring only initial

setup and minimal operator attention.

|

CN3251 CN3251

1/4

DIN Ramp/Soak Temperature/Process Controllers

with Modular Outputs and Communications.

|

|

|

The

CN3251 1/4 DIN temperature and process controller

is a low cost, high performance single loop

controller that can be used for temperature,

flow, pressure and level control applications.

With universal sensor inputs and front panel

operator setup, one CN3251 controller can be

easily field configured for a wide variety of

applications, and simply reconfigured as application

needs change. This makes it an exceptional choice

for applications requiring multiple control

needs, manufacturing facilities, testing facilities

and testing applications.

|

CN3410/3411/3412/3413

Series CN3410/3411/3412/3413

Series

Vertical

1/8 DIN Temperature/Process Ramp & Soak

Controller.

|

|

|

The

CN3410 Series process controller is a highly

versatile, single-loop controller designed to

be exceptionally easy to operate and set up.

Universal input and integral transmitter power

supply ensure that the CN3410 Series has the

capabilities to measure a wide range of process

signals such as temperature, pressure, flow

and level. Analog, dc pulse and relay control

outputs are all fitted as standard, with the

option to add further I/O capabilities such

as additional relays, remote setpoint and digital

input, as needed to suit your application. The

configuration of the CN3410 Series is achieved

simply by moving the security switch and entering

a simple code from the front-panel keys. With

NEMA-3 front-panel protection and superior RF

immunity standard, the CN3410 Series is designed

to function reliably in the harshest of today’s

industrial environments.

|

CN3420

Series CN3420

Series

1/4

DIN Autotune PID Controller with Single Loop

Heat/Cool and 4 Ramp/Soak Segments Standard.

Models: CN3420, CN3421, CN3422, CN3423, CN3424.

|

|

|

The

CN3420 Series Process Controller is a highly

versatile, single loop controller in 1/4 DIN

format that has been designed to be exceptionally

easy to set up and operate. Universal input

and an integral transmitter power supply ensure

that the CN3420 has the capability to measure

a wide range of process signals such as temperature,

pressure, flow and level. The unit features

enhanced performance with analog, logic and

relay control outputs, all fitted as standard,

and an option to add further I/O capabilities

such as additional relays, remote setpoint,

analog retransmission and digital input, as

needed to suit your application. The configuration

of the CN3420 is achieved by moving the security

switch and entering a simple code from the front

panel keys or via our CN34-SW PC configuration

package. There are no passwords, no input links,

no complications. With NEMA-4X/IP66 front panel

and superior RF immunity standard, the CN3420

has been designed to control reliably in the

harshest of today’s industrial environments.

|

CN606

& CN612 Series CN606

& CN612 Series

1/4

DIN Temperature 6 or 12 Channel Monitor with

One Alarm and Communications Standard.

|

|

|

The

CN600 Series are microprocessor-based scanners

which accept the same input type signals from

up to 12 thermocouples or RTD’s. Each zone is

sequentially scanned and active zones are displayed.

Individual zones can be locked for monitoring.

Each instrument is programmable to meet the

operator’s needs for thermocouple or RTD input

type, degree scale, latching or non-latching,

and HI, LO or HI/LO alarms. Memory and setpoints

are retained when power is off. The RS-232 program

can monitor up to ten units. All CN600 Series

Scanners have RS-232 three-wire serial communications.

Up to 10 scanners can be daisy-chained together.

CN600-SOFT software is included with every unit

at no charge. Line voltage is 120 Vac or 240

Vac selectable by external jumper assembly.

On the back of the instrument are easy-to-use

screw terminal connections. The CN600 Series

implements a security password to protect settings.

The password can be enabled or disabled on the

front panel and changed via RS-232. Calibration

is performed from the front panel and is separately

password protected. Higher level passwords are

available. The instrument mounts in a 1/4 DIN

panel cutout and is secured by slide brackets.

It does not have to be removed from its housing

to be mounted. The instrument is housed in a

1/4 DIN aluminum box. Optional models available

are 6 Zone Thermocouple with Output Card, 12

Zone Thermocouple, 6 Zone RTD or 12 Zone RTD.

A single output relay is provided to indicate

an alarm condition on any zone. The instrument

shows an alarm condition by flashing the main

temperature display while indicating the zone

in alarm with a flashing zone number display.

The alarm automatically shuts itself off when

the condition changes in the non-latching setting

and is manually reset in the latching setting.

There are two modes the monitor can be set for:

RUN and FUNCTION SELECT. RUN is the basic operating

mode. FUNCTION SELECT is the password protected

settings selection and control mode. One

of ten functions can be selected: "RUN"

MODE; "FUNCTION SELECT"; Select Active

Zones; Set LO Setpoint; Set HI Setpoint; Serial

Number; Set Scan Time; Select Model; Password

Enable; Calibration.

|

CN616

Series CN616

Series

1/4

DIN 6-Zone Temperature Controllers with RS-232

Communications and Free Configuration Software.

|

|

|

The

CN616 Series is a highly versatile six-loop

microprocessor-based controller designed for

easy front panel or remote setup and operation.

Each of six zones is sequentially scanned, and

active zones are displayed. Individual zones

can be locked for monitoring. Each instrument

is programmable to meet operator needs for:

Thermocouple Type, Temperature units; Hi, Lo

or Hi/Lo Alarm configured as Latching or Non-Latching;

and Autotune with Manual Trim or Manual PID

Setting. The Zone Display Scan Time and Ramp/Soak

can be set by the operator. Parameters and setpoints

are retained when power is turned off. Password

protection is provided to prevent accidental

changes to calibration, PID setting and ramp/soak

profile. If power loss occurs, the controller

retains all the latest parameters and returns

to “Run” mode.

All

CN616 Controllers have RS-232 three-wire serial

communications. The CN616-SOFT communications

software is now included with every CN616 series

at no additional charge. The RS-232 program

is capable of monitoring up to ten daisy-chained

units.

Line

Voltage is 120 Vac or 240 Vac selectable by

external jumper assembly. Connections are made

to the back of the instrument through easy-to-use

screw terminal plugs.

The

CN616 Series implements a security password

to protect settings. The password can be enabled

or disabled on the front panel and changed via

RS-232. Calibration is performed on the front

panel and is separately password protected.

Higher level passwords are available.

The

instrument is housed in a 1/4 DIN aluminum box

which does not have to be removed for mounting.

The unit mounts in a 1/4 DIN panel cutout and

is secured by slide brackets. Control is done

via 6 dc pulse outputs (one for each zone).

A

single output relay is provided to indicate

an alarm condition on any zone. The instrument

shows an alarm condition by flashing the main

temperature display while indicating the zone

in alarm with a flashing zone number display.

When set for Non-Latching, the alarm automatically

resets when the condition changes. The alarm

must be manually reset in the Latching setting.

The

controller functions in two modes: “RUN” is

the basic operating mode. “FUNCTION SELECT”

is the password protected settings selection

and control mode.

|

CN77000 CN77000

1/16

DIN Autotune PID Temperature/Process

Controllers.

|

|

|

High

accuracy, high quality controllers

offer unparalleled flexibility in process control.

Each unit allows the user to select the input

type, from 10 thermocouple types (J, K, T, E,

R, S, B, C, N and J DIN), Pt RTD's (100, 500

or 1000 ohm, with either 385 or 392 curve),

or analog voltage or current input. The voltage/current

inputs are fully scalable to engineering units,

with selectable decimal point, perfect for use

with pressure, flow or other process input.

The controller features a large,

dual LED display, front panel configuration,

selectable temperature/ process inputs and universal

power supply that accepts 90 to 250 Vac or Vdc.

Available in single and dual output configurations,

the CN77000 Series is available with relay,

SSR, dc pulse, analog voltage or current outputs.

A single alarm is standard. Options include

a second alarm, RS-232, RS-485, analog output

or remote setpoint selection. The CN77300 series

controllers have many features of larger, 1/4

DIN controllers in a compact, 1/16 DIN size.

These controllers feature a 1/16 DIN cutout

and bezel with a NEMA-12 rating, dual LED displays,

with different colors for the actual process

and setpoint values. Individual indicators provide

output and alarm status. The CN77500 series

features a 1/16 DIN cutout, 53.3 mm (2.1")

square face with NEMA-4 rating, large dual LED

display, front panel configuration, and selectable

temperature/ process inputs. Available in single

and dual output configurations, the CN77500

is available with relay, SSR, dc pulse, analog

voltage or current outputs. A single alarm is

standard. The CN77R300 and CN77R500 series controllers

feature a unique detachable display and adapter

to allow mounting in a round, 44 mm (1.75")

cutout. This feature allows users to prepare

the panel with a standard round hole saw. The

2-piece design snaps together, for quick, easy

installation.

|

Input Type |

Range |

Accuracy |

|

J |

Iron-Constantan |

-210 to 760°C/-346 to 1400°F |

0.4°C/0.7°F |

|

K |

CHROMEGA®-

ALOMEGA® |

-270 to -160°C/-160 to 1372°C

-454 to -256°F/-256 to 2502°F |

1.0°C/0.4°C

1.8°F/0.7°F |

|

T |

Copper-

Constantan |

-270 to -190°C/-190 to 400°C

-454 to -310°F/-310 to 752°F |

1.0°C/0.4°C

1.8°F/0.7°F |

|

E |

CHROMEGA®-

Constantan |

-270 to -220°C/-220 to 1000°C

-454 to -364°F/-364 to 1832°F |

1.0°C/0.4°C

1.8°F/0.7°F |

|

R |

Pt/13%Rh-Pt |

-50 to 40°C/40 to 1768°C

-58 to 104°F/104 to 3214°F |

1.0°C/0.5°C

1.8°F/0.9°F |

|

S |

Pt/10%Rh-Pt |

-50 to 100°C/100 to 1768°C

-58 to 212°F/212 to 3214°F |

1.0°C/0.5°C

1.8°F/0.9°F |

|

B |

30%Rh-Pt/6%Rh-Pt |

100 to 640°C/640 to 1820°C

212 to 1184°F/1184 to 3308°F |

1.0°C/0.5°C

1.8°F/0.9°F |

|

C |

5%Re-W/26%Re-W |

0 to 2320°C/32 to 4208°F |

0.4°C/0.7° |

|

N |

Nicrosil-Nisil |

-250 to -100°C/-100 to 1300°C

-418 to -148°F/-148 to 2372°F |

1.0°C/0.4°C

1.8°F/0.7°F |

|

L |

J DIN |

-200 to 900°C/-328 to 1652°F |

0.4°C/0.7°F |

|

RTD |

Pt, 0.00385, 100Ω, 500Ω, 1000Ω |

-200 to 900°C/-328 to 1652°F |

0.4°C/0.7°F |

|

Pt, 0.00392, 100Ω, 500Ω, 1000Ω |

-200 to 850°C/-328 to 1562°F |

0.4°C/0.7°F |

|

|

Process Voltage |

0 to 100 mV, 0 to 1 V, 0 to 10 Vdc |

0.03% rdg |

|

|

Process Current |

0 to 20 mA, 4 to 20 mA |

0.03% rdg |

|

|

CN800

Series CN800

Series

1/16

DIN Proportional or On-Off Temperature Controllers

with Dedicated Inputs & Ranges.

|

|

|

SPECIFICATIONS

Power:

115/230 Vac, user-selectable; 50 to 60 Hz; preset

to 115 Vac

Power

Consumption: 3 VA

Output

1: SPDT mechanical relay, rated 5 A at 250 Vac,

resistive load

Output

2: SPDT mechanical relay, rated 3 A at 250 Vac,

resistive load

Setpoint

1: front dial adjustment

Setpoint

2: screwdriver adjustment within ±10%

of temperature range relative to setpoint 1

Accuracy:

2% FS, within 5 to 95% or range

Accuracy

Reference Conditions: 22°C ±2°C

(72°F ±3.6°F), after 30 min.

warm-up time

Proportional

Band: 3% FS fixed Cycle Time: 25 s, nominal,

fixed

On-Off

Deadband: 2% FS, Fixed

Input

Types: J, K, T, R, S thermocouples; 100 ohm

Pt RTD, 2- or 3-wire

Sensor

Burnout: upscale, automatic

Common

Mode: negligible effect to 264 Vrms, 50/60 Hz

Normal

Mode: negligible effect to full scale mV, 50/60

Hz

Ambient

Temperature Range: to 50°C (32 to 130°F)

Dimensions:

48 H x 48 W x 97 mm D (1.89 x 1.89 x 3.8")

Panel

Cutout: 45 mm (1.772") square

Weight:

250 g (9 oz)

|

|

CN8100

Series CN8100

Series

1/4

DIN, PID, On/Off, or Limit Controllers.

|

|

|

The

CN8100 Series may be ordered as either a PID

or On/Off controller or as a Limit Safety Device.

The ¼ DIN models are low cost and ideal

for OEM or replacement applications. They are

microprocessor-based and accurate to ±0.3%

FS. As a separate safety feature to your control

application, the CN8121-R1 high limit safety

device provides reliable high/low temperature

limit shut-off control for most machine and

process control applications including environmental

chambers, furnaces, ovens and packaging machinery.

As a high limit device, these controllers have

a normally energized SPDT latching output relay

which becomes de-energized whenever the process

variable (PV) exceeds a selected setpoint value.

Reset of the latching output relay is done from

a reset pushbutton on the front panel of the

controller.

|

|

CN8201

and CN8202 Series CN8201

and CN8202 Series

1/16

Din Universal Temperature & Process Controllers

with 8 Segment Ramp/Soak Capability.

|

|

|

The

CN8200 temperature/process controller is extremely

versatile and user-friendly. The operator needs

to review only those parameters relevant to

the particular application during setup. A dual

digital display offers optimum process information

at a glance. Individual LED's identify the status

of outputs, alarms, digital communications,

and special options. The CN8200 features a NEMA-4X

front panel and a universal power. supply that

accepts 100 to 250 Vac and 120 to 250 Vdc. A

24 Vac/24 Vdc power supply option is also available.

Control algorithms available are P, PI, PD,

PID, or ON/OFF. The autotune feature automatically

sets proportional band, derivative, and integral

before the process reaches setpoint. These parameters

provide quick stabilization of processes with

minimum overshoot, hunting, or cycling. Eight-level

ramp/soak control is standard, and includes

a decimal display on thermocouple ranges, digital

display and signal filtering, and a percentage

of power limit setting. The dual control outputs

can be configured for a variety of control and

alarm applications, and two dedicated alarm

outputs are also available. The CN8200 offers

a wide range of options, including RS-232 and

RS-485 digital communications, five remote analog

setpoint ranges, three contact/digital input

modes, four transducer excitation voltages,

and four auxiliary output ranges.

|

|

CN8240

and CN8260 Series CN8240

and CN8260 Series

1/8

DIN Verttical and 1/4 DIN Universal Input Temperature/Process

Controllers.

|

|

|

The

CN8240/CN8260 1/8 DIN vertical and 1/4 DIN temperature/

process controllers are extremely versatile

and user-friendly. The operator needs to review

only those parameters relevant to the particular

application during setup. A dual digital display

offers optimum process information at a glance.

The dedicated upper display shows the process

value, while the lower display shows setpoint

and setup parameters. Individual LED's identify

the status of outputs, alarms, digital communications,

and special options. The CN8240/CN8260 features

a NEMA-4X front panel and a universal power

supply that accepts 100 to 250 Vac and 120 to

250 Vdc. A 24 Vac/24 Vdc power supply option

is also available. Calibrations for most thermocouples

and RTD's are available, as well as for millivolt

linear, volt linear, and current linear inputs.

Unlike the CN8200 1/16 DIN models, these controllers

have plug-in output modules that can be changed

in the field. In addition, a single output model

can be converted to a dual output version in

the field. Control algorithms available are

P, PI, PD, PID, or ON/OFF. The autotune feature

automatically sets proportional band, derivative,

and integral before the process reaches setpoint.

These parameters provide quick stabilization

of processes with minimum overshoot, hunting,

or cycling. Eight-level ramp/soak control is

standard, and includes decimal display on thermocouple

ranges, digital display and signal filtering,

and a percentage of power limit setting. The

dual control outputs can be configured for a

variety of control applications, and an additional

two dedicated alarm outputs are also available.

The CN8240/CN8260 offers a wide range of options,

including RS-232, RS-485 digital communications,

a variety of remote setpoint options, three

contact/digital input modes, four transducer

excitation voltages, and four auxiliary output

ranges.

|

|

CN8590

Series CN8590

Series

1/32

DIN Autotune, Temperature/Process Dual Output

Controllers.

|

|

|

The

CN8590 is a 1/32 DIN microprocessor based controller

that provides accurate closed-loop control of

temperature and other process variables. With

on-demand auto-tuning, and complete On/Off through

full PID functionality, the CN8590 accepts inputs

from K, J and T type thermocouples, RTD's or

linear signals. Standard features include a

large easy-to-read LED display, dual outputs,

field selectable inputs, process or deviation

high/low alarms, and bumpless auto/manual transfer.

On/Off output hysteresis is adjustable and the

unit may be easily configured in the field to

display process value, deviation or output percentage.

|

|

CN9000A

Series CN9000A

Series

1/16

DIN Autotune PID/On-Off Controllers with Modular

Output Options.

|

|

|

The

CN9000A digital temperature controllers feature

high accuracy and reliability, and the sophisticated

PID with approach control for optimal control

during start-up and steady-state operation.

These units are well suited for a broad range

of applications, and are easy to install and

operate. The unique, sophisticated autotune

algorithm will calculate the optimum PID values,

and additionally recommends the best value for

cycle time. For most applications, the user

need only select the desired input type, simply

by using the front pushbuttons. The autotune

parameters can be changed by the operator at

any time, allowing the operator to fine tune

the controller to an individual process. The

microprocessor holds all data in non-volatile

memory, with the ability to retain data for

10 years with no power. The CN9000A has a large,

3 1/2 digit green LED readout, with auxiliary

indicators for each output, and 3 LED’s to indicate

deviation from setpoint. Selection of all operational

controls is made through the keys on the front

panel, with the display prompting the user through

each step. After the parameters have been set,

they can be locked in, simply by removing a

jumper located behind the front bezel. The user

can select the control mode and parameters,

display resolution (1 or 0.1°), and units

(°F/°C). The operator can also utilize

the ranging feature, which limits the range

in which the setpoint may be chosen, or lock

out a user from changing the setpoint. The new

single setpoint controller has rear termination.

The optional second setpoint and output of the

CN9000A model can be set for proportional, on-off

or latching limit control, and can be set as

either a tracking or non-tracking setpoint.

Cycle time, proportional band and on-off deadband

are all set independently of the primary setpoint.

|

|

CN9300,

CN9400, CN9500 and CN9600 Series CN9300,

CN9400, CN9500 and CN9600 Series

1/32

& 1/16 DIN Temperature/Process Autotune

Controllers with Optional Plug-in Communications

and CN9-SW Cloning, Logging & Charting Software.

|

|

|

The

new 1/32 DIN CN9500, 1/16 DIN CN9300 Single

Display and 1/16 DIN CN9400 Dual Display controllers

follow our tradition of innovative design.

Building on the success of the CN132 and CN9000A

series, the new models include several new features,

the most important being the option of a low

cost serial communicating system with easy to

use Windows-based software. The CN9-SW series

software bridges the gap between the "stand

alone" system and full SCADA of Fieldbus

control networks by providing a facility for

remote supervision of up to 32 instruments using

MODBUS protocol. It requires only a modest investment

and can be operated by anyone with a medium

specification PC or laptop that can be run with

Windows 95 or Windows NT.

|

|

CNi

Series Family CNi

Series Family

i-Series

1/32, 1/16, 1/8 DIN Programmable Temperature/Process

Controllers with RS-232 & RS-485 Communications.

|

|

|

The

innovative OMEGA® iSeries of meters/controllers

combines in one intelligent industrial instrument

features of an extremely accurate digital panel

meter and a fully functional PID controller.

The iSeries instruments are simple to

configure and use, while providing tremendous

versatility and a wealth of powerful features.

i/8,

i/16, i32 FAMILY

The

iSeries is a family of microprocessor-based

instruments offered in three true DIN sizes

with NEMA-4, IP65 rated front bezels. All of

the instruments share the same set-up and configuration

menu and method of operation, a tremendous time

saver for integration of a large system.

Programmable

Color Display

The

i/8, i/16, and i/32 are the first

complete series of 1/8, 1/16 and 1/32 DIN process

control instruments with totally programmable

color displays. The display can be programmed

to change color at any setpoint or alarm point.

For example, the instrument can be programmed

to display the Process Value in GREEN during

warm-up, switching to AMBER to signal the normal

operating range, and in RED to signal an alarm

condition. The changes in color are quickly

seen from a distance, and machine operators

can intuitively react to changing conditions.

In

another example, the instrument can be programmed

to display GREEN for normal, AMBER to signal

a minor alarm condition, and RED for a major

alarm. The colors can be programmed to change

back when the value drops back below the alarm

point or to "latch" on until being

reset by the operator.

The

instrument can also be programmed to display

only one unchanging color: GREEN, AMBER, or

RED. This is a useful way to let an operator

identify, at a glance, process values in three

separate locations, or to display three different

measurements such as Temperature, Pressure,

and Flow. The innovative iSeries

of meters/controllers features an extended Five

(5) YEAR warranty at no extra charge. The iSeries

packs a wealth of power and features into the

smallest of packages, utilizing COB (chip-on-board)

and SMT (surface mount technology) assembly

techniques and automation. Every iSeries instrument

is thoroughly calibrated and tested at several

stages throughout production. The iSeries offers

the highest accuracy for industrial instrumentation

at 0.03% of reading. The analog-to-digital conversion

utilizes proprietary 20-bit ASIC (application

specific integrated circuit) patented algorithms

and smart filtering.

Universal

Inputs

The

innovative iSeries offers the broadest selection

of signal inputs available on one industrial

instrument. The choices are easily selected

from the Menu with four front panel pushbuttons,

or by serial communications. 10 Thermocouple

Types. The iSeries handles TEN (10) thermocouple

types: K, J, T, E, R, S, B, C, N, and J DIN.

The patented thermocouple linearization algorithms

employed in the iSeries produce the highest

standard of accuracy.

Most

Accurate RTD Measurements

The

iSeries works with the widest selection of RTD’s

and produces the most accurate RTD measurements.

Both Pt 0.00385 and 0.00392 curves. 100 (ohm),

500 (ohm) and 1000 (ohm). A choice of 2-, 3-

and 4-wire RTD connections ensures the absolute

highest degree of accuracy.

Process

Voltage and Current

The

OMEGA® iSeries measures process voltage:

0-100 millivolt, 0-1 Volt, 0-10 Volt ranges,

and process current: 0-20 mA.

Analog

Output

The

optional analog output can be programmed within

a range of 0-10 Vdc or 0-20 mA. It is selectable

as either a control output or as a calibrated

retransmission of the process value-a unique

feature among controllers.

Built-in

Excitation Standard

The

iSeries comes standard with built-in 24 Vdc

@ 25 mA excitation for transmitters or other

devices. This means the same instrument can

handle thermocouples, RTD’s, and 4-20 mA transmitters,

with its own excitation. (Built-in excitation

is not available with optional Isolated RS-232/RS-485

Serial communications.)

Control

Functions

The

iSeries can control simple manual operation

to ON-OFF and full Autotune PID control. (Selectable

preset tune, adaptive tune, PID, PI, PD control

modes.) The dual control outputs can be configured

for a variety of independent control and alarm

applications such as heat/heat, heat/cool, heat/alarm,

cool/cool, cool/alarm or alarm/alarm. The ramp-to-setpoint

feature allows the user to define the rate of

rise to setpoint, minimizing thermal shock to

the load during start-up. Maximum ramp time:

99.59 (HH.MM), Soak: 00.00 to 99.59 (HH.MM),

Damping: 1 to 8 in unit steps. Input types:

J, K, T, E, R, S, B, C, N, J-DIN, RTD 100 ohm,

500 ohm & 1k ohm in 0.00385 or 0.00392,

0 to 20 mA, 0 to 100 mV, 0 to 1 V and 0 to 10

Vdc.

Free

Software

Free

interface software is provided for easy set-up,

configuration and data acquisition with the

OMEGA® iSeries. (Picture at right is an

example of software that might be used).

Free

ActiveX Controls

Free

ActiveX Controls are provided for the iSeries,

making it easy to integrate the iSeries with

information systems using "ActiveX Containers"

such as Microsoft Visual Basic and Microsoft

Excel as well as with popular OLE and OPC compliant

data acquisition, process control, and industrial

automation software from OMEGA®, GE Fanuc,

Intellution, Rockwell Automation, Object Automation,

iconics, and Wonderware among others.

Optional

Isolated RS-232 and RS-485 Serial Communications

The

iSeries are the first intelligent industrial

instruments to offer both RS-232 and RS-485

serial communications in one instrument which

can be selected from the menu.

The

iSeries features both serial protocol

and MODBUS serial protocol.

Free

Factory Setup and Configuration

Make

installating your iSeries meter or controller

easier by ordering it preconfigured by the factory,

at no extra charge. You specify the input types,

scaling if applicable, set points, alarm points,

etc. and we will program the instruments to

your specific requirements in our calibration

lab prior to shipment. For a checklist of factory

setup parameters, please consult your OMEGA®

applications engineers.. The Factory Setup and

configuration option requires the serial communication

"-C24" option.

Custom

Configurations

Custom

color bezels and enclosures are available for

Original Equipment Manufacturers. Enhance the

appearance of your equipment design with custom

colors. Consult the OMEGA® OEM Group. i

Series LED displays are considerably bigger,

brighter and therefore more visible than displays

for conventional instruments with the same DIN

size. The segments in the i/8 are 21 mm (.83")

high.

|

|

Input

Type |

Range |

Accuracy |

|

Process

Voltage |

0 to 100 mV,

0 to 1 V, 0 to 10 Vdc |

0.03%

rdg |

|

Process

Current |

0 to 20

mA |

0.03%

rdg |

|

J |

Iron-Constantan |

-210 to 760°C

/ -346 to 1400°F |

0.4°C /

0.7°F |

|

K |

CHROMEGA®-ALOMEGA® |

-270 to

-160°C / -160 to 1372°C

-454 to -256°F / -256 to 2502°F |

1.0°C /

0.4°C

1.8°F / 0.7°F |

|

T |

Copper-Constantan |

-270 to

-190°C / -190 to 400°C

-454 to -310°F / -310 to 752°F |

1.0°C /

0.4°C

1.8°F / 0.7°F |

|

E |

CHROMEGA®-Constantan |

-270 to

-220°C / -220 to 1000°C

-454 to -364°F / -364 to 1832°F |

1.0°C /

0.4°C

1.8°F / 0.7°F |

|

R |

Pt/13%Rh-Pt |

-50 to 40°C /

40 to 1768°C

-58 to 104°F / 104 to 3214°F |

1.0°C /

0.5°C

1.8°F / 0.9°F |

|

S |

Pt/10%Rh-Pt |

-50 to 100°C

/ 100 to 1768°C

-58 to 212°F / 212 to 3214°F |

1.0°C /

0.5°C

1.8°F / 0.9°F |

|

B |

30%Rh-Pt/6%Rh-Pt |

100 to 640°C

/ 640 to 1820°C

212 to 1184°F / 1184 to 3308°F |

1.0°C /

0.5°C

1.8°F / 0.9°F |

|

C |

5%Re-W/26%Re-W |

0 to 2320°C /

32 to 4208°F |

0.4°C /

0.7°F |

|

N |

Nicrosil-Nisil |

-250 to

-100°C / -100 to 1300°C

-418 to -148°F / -148 to 2372°F |

1.0°C /

0.4°C

1.8°F / 0.7°F |

|

L |

J

DIN |

-200 to 900°C

/ -328 to 1652°F |

0.4°C /

0.7°F |

|

RTD |

Pt, 0.00385,

100ohm, 500ohm, 1000ohm |

-200 to 900°C

/ -328 to 1652°F |

0.4°C /

0.7°F |

|

RTD |

Pt, 0.00392,

100ohm, 500ohm, 1000ohm |

-200 to 850°C

/ -328 to 1562°F |

0.4°C /

0.7°F |

|

|

CNI8C

and CNIS8C CNI8C

and CNIS8C

1/8

DIN Ultra Compact Case Temperature, Process

and Strain PID Controllers. Ultra Compact

1/8 DIN Meter and Controller. Big Display with

Color Changing Feature. Built-in Excitation. NEMA

4 (iP65) Bezel. RS-232, RS 422/485 or Modbus

Communication, Menu Selectable.

|

|

|

/8

and i/32 FAMILY

The

OMEGA® iSeries is a family of microprocessor-based

instruments offered in two true DIN sizes with

NEMA-4, IP65 rated front bezels. All of the

instruments share the same set-up and configuration

menu and method of operation, a tremendous time

saver for integration of a large system.

The

iSeries displays feature unique 9-segment LED

characters which greatly improves alphanumeric

representations. The 7-segment LED characters

found on most instruments are adequate for presenting

numbers, but not letters. Words are easier to

read with the unique 9-segment LED characters

on the iSeries, which makes operating and programming

simpler and easier.

|

|

|

|

Programmable

Color Display

The

iSeries are the first complete series of 1/8,

1/16 and 1/32 DIN process control instruments

with totally programmable color displays. The

display can be programmed to change color at

any set point or alarm point.

|

|

|

|

|

For

example, the instrument can be programmed to

display the process value in GREEN during warm-up,

switching to AMBER to signal the normal operating

range, and in RED to signal an alarm condition.

The changes in color are quickly seen from a

distance, and machine operators can intuitively

react to changing conditions. The colors can

be programmed to change back when the value

drops back below the alarm point or to "latch"

on until being reset by the operator. The instrument

can also be programmed to display only one unchanging

color: GREEN, AMBER, or RED. This is a useful

way to let an operator identify, at a glance,

process values in three separate locations,

or to display three different measurements such

as Temperature, Pressure, and Flow.

|

|

CNiS32

& DPiS32 Series CNiS32

& DPiS32 Series

i-Series

1/32 DIN Programmable Strain/ Process Controllers

and Meters with RS-232 & RS-485 Communications

Featuring a Totally Programmable Color Display.

|

|

|

The

iS32 series of meter/controllers can measure

a wide variety of DC voltage and current outputs

for all common load cells, pressure transducers,

and most any strain gauge type of transducer.

It is the first instrument of its kind, offering

a wealth of powerful features and performance

in an amazingly compact 1/32 DIN package. The

iS32 handles input ranges of 0-100 mV, 0-1 V,

0-10 V, 0-20 mA (4-20 mA). The iS32 is easy

to configure and scale to virtually any engineering

units using the push buttons on the front panel,

or using personal computer with the optional

serial communications and free configuration

software. The serial communications option includes

both RS-232 and RS-485 on one instrument, and

the straightforward OMEGA ASCII communications

protocol, as well as MODBUS protocol. The iS32

includes built-in excitation for transducers,

selectable as 10 V at 100 mA or 5 V at 60 mA.

The iS32 features a choice of two optional outputs:

Form C SPDT (single pole double throw) mechanical

relays, solid state relays, DC pulse, and programmable

analog output selectable for either a control

function or retransmission of the process value.

The iS32 features the iSeries totally programmable

color display that can change colors between

Green, Amber, and Red at any setpoint or alarm

point.

|

|

CNiTH

and DPiTH Series CNiTH

and DPiTH Series

Humidity +

Temperature Controllers.

|

|

|

The

instruments are simple to configure and use,

while providing tremendous versatility and a

wealth of powerful features. The Omega iTH Series

instruments are available either as monitors

or controllers. The monitors are extremely accurate

programmable digital panel meters displaying

humidity, temperature, or dew point. The controllers

also provide dual loop control for both humidity

and temperature and are easily programmed for

any control or alarming requirement from simple

on-off to full autotune PID control. The iTH

family of meters and controllers are available

in four true DIN Sizes with NEMA 4, IP65 splash

resistant bezels: the ultra compact 1/32 DIN

(the world's smallest dual loop Humidity + Temperature

controller); the popular midsize 1/16 DIN square

bezel with dual display; the 1/8 DIN vertical,

and the 1/8 DIN horizontal with the big bright

21mm digits. The iTH series LED displays can

be programmed to change color between Green,

Amber, and Red at any set point or alarm point.

The iTH controller models offer a choice of

two control or alarm outputs in almost any combination:

solid state relays (SSR); Form "C"

SPDT (Single Pole Double Throw) relays; pulsed

10 Vdc output for use with an external SSR;

or Analog Output selectable for control or retransmission

of the process value. The Networking and Communications

options (highly recommended) include direct

Ethernet LAN connectivity with an Embedded Web

Server, and serial communications. The C24 serial

communications option includes both RS-232 and

RS-485. Protocols include both MODBUS and a

straightforward ASCII protocol. The C4EI option

includes both Ethernet and RS-485 ASCII/MODBUS

on one device. The iTH Series meters and controllers

are designed for easy integration with popular

industrial automation, data acquisition and

control programs as well as Microsoft Visual

Basic and Excel. Omega® provides free configuration

and data acquisition software and demos which

makes it fast and easy to get up and running

with many applications.

|

|

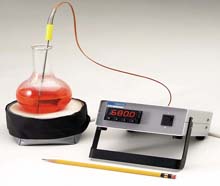

CPP940

& CBC990 Series CPP940

& CBC990 Series

Low

Cost Compact Temperature Controllers for Lab

Heaters.

|

|

|

The

OMEGALUX® percentage controller is a manually

adjustable control which provides variable selection

of average heater power. The controller varies

the proportion of “off” and “on” time of the

heater. Thermal characteristics of the heated

item will determine the setting of the manually

adjustable controller knob. The controller does

not use a temperature sensor; therefore, operation

requires occasional supervision under changing

load conditions.

Applications

OMEGALUX®

percentage controllers are designed for indoor

use to control the temperature of small tanks,

laboratory heaters, pipes, and drums in which

the control of average power is desired and

precise control is not required. CBC controllers

are designed for indoor use to control the temperature

of small tanks, drums, pipes or other applications

requiring automatic temperature control.

The

OMEGALUX® Series CBC controller utilizes

a bulb and capillary type sensor to control

a single pole, single throw switch. Once the

temperature is set, it is automatically maintained

by the controller. The control is housed in

a rugged cast aluminum enclosure and has an

easy-to-read dial. No wiring is required, as

the heater is plugged into the control unit.

|

|

CSC32 CSC32

Compact

CN9500 Controller in Rugged Benchtop Case.

|

|

|

The

CSC32 series compact benchtop controllers are

ideal for laboratory use and applications requiring

portable temperature and process control. Pre-wired

input and output receptacles in the rear of

the case enable quick and easy connections to

power, input, power output and digital communications.

These benchtop controllers are factory configured

and calibrated for a dedicated input type by

model number. The 1/32 DIN CN9500 controller

used in this benchtop controller series can

be programmed for either On/Off, or PID Autotune

Control (with autotune Feature) via the front

panel or through the use of a PC and CN9-SW

communications software.

CN9-SW

software is designed to interface with the CN9300,

CN9400, CN9500 and CSC32 Series benchtop controllers

with optional communication hardware. Benefits:

Time saving benefit and convenience of remotely

configuring and adjusting units; Saving and

retrieving settings to and from files; Highly

flexible logging and “real time” charting capability

for providing hard copy QA records for ISO-9000

and other management purposes; Software is capable

of logging readings from up to 128 instruments

which it stores in data files; The data can

be exported into text files in Comma Separated

Variable format; In addition, up to 12 controllers

can be displayed on a single chart, or individual

charts can be set up for each instrument; A

Virtual full color chart recorder can log process

variables such as: °C, °F, Bar, PSI,

pH, rH, or user defined engineering units .

|

|

DP26

Series DP26

Series

1/8

DIN Dual Input Indicator/Controller which can

be used for Differential Temperature Measurement.

|

|

|

The

DP26 differential temperature meter is a versatile

dual input indicator/controller. The touch of

a button toggles the display between T1, T2

and T1-T2. Analog output is optional, using

any of the three values available. The optional

control relays for alarms or on-off control

can be tied to T1, T2 or T1-T2. The user selects

J, K, T or J DIN thermocouple input from the

front panel. The units of measure can be switched

between °F and °C with the front panel

pushbuttons. The optional analog output can

function as retransmission of temperature (assignable

to T1, T2, or T1-T2) or be assigned to Setpoint

#1 and used as a proportional control output.

Setpoint #1 will still continue to operate as

a setpoint, while the analog output of either

4-20 mA or 0-10 V can be used to proportionally

control an external process.

|

|

DP41-B DP41-B

1/8

DIN ULTRA HIGH PERFORMANCE METER

|

|

|

The

all new DP41-B raises the bar even higher with

accuracy of up to ±0.005% of reading,

and up to 166 readings per second. The versatile

DP41-B handles a broad spectrum of dc voltage

and current ranges, nine thermocouple types,

multiple RTD's, and signals from strain gauge

transducers such as load cells and pressure

transducers, as well as potentiometric inputs.

It also features ten point linearization of

input signals, progammable by the user for custom

applications. Built-in excitation to power virtually

any sensor or transmitter, and four isolated

open collector outputs for control or alarms

are standard. The big, bright, 6 digit patented

LED display can be programmed to change color

between Red, Amber, and Green at any set point.

The digits are 58% bigger than the typical display.

Output options include: Isolated programmable

analog voltage or current and four relays.

With

the Serial Communications option, the user can

select from a push-button menu between RS-232,

RS-485, and either a straightforward ASCII protocol

or MODBUS. With OMEGA’S award-winning Ethernet/Internet

option, the new DP41-B connects directly to

an Ethernet network and transmits data in standard

TCP/IP protocol. It is possible to monitor and

control a process through a web browser from

anywhere on the Internet.

Embedded

Internet and Serial Communications

Featuring

optional "Embedded Internet" (specify

EI option) the DP41-B connects directly to an

Ethernet network and transmit data in standard

TCP/IP packets, or even serve Web pages over

a LAN or the Internet. The DP41-B is also available

with serial communications. With the C24 option,

the user can select from the push-button menu

between RS-232, RS-422, and RS-485, with straightforward

ASCII commands or MODBUS.

Programmable

Color Display

The

DP41-B has totally programmable color displays.

The display can be programmed to change color

at any set point or alarm point. For example,

the instrument can be programmed to display

the process value in GREEN during warm-up, switching

to AMBER to signal the normal operating range,

and in RED to signal an alarm condition. The

changes in color are quickly seen from a distance,

and machine operators can intuitively react

to changing conditions. The colors can be programmed

to change back when the value drops back below

the alarm point or to "latch" on until

being reset by the operator.

The

instrument can also be programmed to display

only one unchanging color: GREEN, AMBER, or

RED. This is a useful way to let an operator

identify, at a glance, process values in three

separate locations, or to display three different

measurements such as Temperature, Pressure,

and Flow. DP41-B LED displays are considerably

bigger, brighter and therefore more visible

than displays for conventional instruments with

the same DIN size.

QUALITY

and TECHNOLOGY

Designed

and manufactured, the innovative DP41-B meters

feature an extended five (5) YEAR warranty at

no extra charge. The DP41-B packs a wealth of

power and features using COB (chip-on-board)

and SMT (surface mount technology) assembly

techniques and automation. Every DP41-B instrument

is thoroughly calibrated and tested at several

stages throughout production. The DP41-B offers

the highest accuracy for industrial instrumentation

at 0.005% of reading. The analog-to-digital

conversion utilizes patented algorithms and

smart filtering.

Universal

Inputs

The

innovative DP41-B offers the broadest selection

of signal inputs available on one industrial

instrument. The choices are easily selected

from the menu with four front panel pushbuttons,

or by serial or ethernet communications.

9

Thermocouple Types

The

DP41-B handles NINE (9) thermocouple types:

K, J, T, E, R, S, B, N, and J DIN. The patented

thermocouple linearization algorithms employed

in the DP41-B produce the highest standard of

accuracy.

Most

Accurate RTD Measurements

The

DP41-B works with the widest selection of RTD's

and produces the most accurate RTD measurements.

Handles 100 ohm Pt both 0.00385 and 0.00392

curves. Any 6 to 6000 ohm NIST or DIN Pt and

any linear RTD (10 ohm Cu, etc.). A choice of

2-, 3- and 4-wire RTD connections ensures the

absolute highest degree of accuracy.

Process

Voltage and Current

The

DP41-B measures process voltage: 0-100 mV, 0-1

V, 0-10 V, 0-100 V (unipolar), ±50 mV,

±500 mV, ±5 V, ±50 V (bipolar)

ranges, and process current: 0-20 mA or 4-20

mA.

Strain

Gauge

The

DP41-B measure inputs from Load Cells, Pressure

Transducers, and most any strain gauge sensor.

Input can be linearized over 10 pts on ranges.

0-100 mV, 0-1 V, 0-10 V, 0-100 V (unipolar),

±50 mV, ±500 mV, ±5 V,

±50 V (bipolar), in addition to 0-20mA.

Excitation for transducers of 10 Volt and 24

Volt is standard.

Analog

Output

The

optional analog output can be programmed within

a range of 0-10 Vdc or 0-20 mA. It is selectable

as a calibrated retransmission of the process

value.

Built-in

Excitation Standard

The

DP41-B comes standard with built-in excitation.

You can capture and display both peak and valley

levels of your input signals, an important feature

for such applications as destructive and pressure

testing. Five different kinds of excitation

are available for sensors such as transmitters

(24 Vdc @ 25 mA), strain gages (1.5 to 10 Vdc

@ up to 60 mA max.), slide-wire potentiometers

(1.25 Vdc @ 30 mA).

The

DP41-B features plug/removable connectors and

a sturdy panel mounting sleeve with adjustable

thumb nuts for easy secure installation

The

DP41-B displays feature unique 9-segment LED

characters, which greatly improves alphanumeric

representations. The 7-segment LED characters

found on most instruments are adequate for presenting

numbers, but not letters. Words are easier to

read with the unique 9-segment LED characters

on the DP41-B, which makes operating and programming

simpler and easier.

Free

Software

Free

software is provided for easy set-up, configuration

and data acquisition with the DP41-B.

Free

ActiveX Controls

Free

ActiveX Controls are provided for the DP41-B,

making it easy to integrate the DP41-B with

information systems using "ActiveX Containers"

such as Microsoft Visual Basic and Microsoft

Excel as well as with popular OLE and OPC compliant

data acquisition, process control, and industrial

automation software from, GE Fanuc, Intellution,

Rockwell Automation, Object Automation, iconics,

and Wonderware among others.

Free

Factory Setup and Configuration

Make

installing your DP41-B meter or controller easier

by ordering it preconfigured by the factory,

at no extra charge. You specify the input types,

scaling if applicable, set points, alarm points,

etc. and we will program the instruments to

your specific requirements in our calibration

lab prior to shipment. For a checklist of factory

setup parameters, please consult your applications

engineers. The Factory Setup and configuration

option requires the serial communication "-C24"

option.

|

Input

Type |

Range, °F

|

Range,

°C |

Range,

°K |

Accuracy* |

|

J |

Iron-Constantan |

-346 to

1400°F |

-210 to

760°C |

63.2 to

1673.2°K |

0.2°C/0.3°F/0.2°K |

|

|

Chromel-Alumel |

-418 to

2282°F |

-250 to

1250°C |

23 to

977.2°K |

0.2°C/0.3°F/0.2°K |

|

T |

Copper-Constantan |

-454 to

752°F |

-270 to

400°C |

3.2 to

673.2°K |

0.2°C/0.3°F/0.2°K |

|

E |

Chromel-Constantan |

-454 to

1832°F |

-270 to

1000°C |

3.2 to

1273.2°K |

0.2°C/0.3°F/0.2°K |

|

R |

Pt

/ 13%Rh-Platinum |

-58 to

3214°F |

-50 to

1768°C |

223.2 to

2041.2°K |

0.2°C/0.3°F/0.2°K |

|

S |

Pt

/ 10%Rh Platinum |

-58 to

3214°F |

-50 to

1768°C |

223.2 to

2041.2°K |

0.2°C/0.3°F/0.2°K |

|

B |

Pt/30% Rh-Pt

/ 6% Rh |

+212 to

3300°F |

+100 to

1820°C |

373.2 to

2093.2°K |

0.3°C/0.5°F/0.3°K |

|

N |

OMEGAALLOY

Nicrosil-Nisil |

-454 to

2372°F |

-270 to

1300°C |

3.2 to

1573.2°K |

0.2°C/0.3°F/0.2°K |

|

J

DIN |

Iron-Constantan |

-328 to

1652°F |

-200 to

900°C |

73.2 to

1173.2°K |

0.6°C/1.0°F/0.6°K |

* Includes (All±) Maximum

Linearization Error

*1 - For K Type: Temperatures over 1250°C,

accuracy will be 0.4°C/0.8°F/0.4°K

*Accuracy (all±) includes maximum

linearization error

|

Input

Type |

Range,

°F |

Range,

°C |

Range,

°K |

Accuracy* |

|

RTD 1

- 10ohm Copper |

-328 to

392°F |

-200 to

200°C |

73.2 to

473.2°K |

1.0°C/2.0°F/1.0°K |

|

RTD 2 -

0.00385 100ohm Pt |

-328 to

1652°F |

-200 to

900°C |

73.2 to

1173.2°K |

0.2°C/0.3°F/0.2°K |

|

RTD 3 -