Microprocessor

Based Turbidity Meter Model ANALITE 160 Microprocessor

Based Turbidity Meter Model ANALITE 160

|

|

The

ANALITE 160 turbidity meter is the latest of our range

of turbidity measurement instruments. It is designed

to operate with either an ANALITE retro-scatter (180°)

probe or an ANALITE 90° probe - to be specified

at time of order. The ANALITE 160 turbidity meter allows

the user to set up measurement parameters through a

user friendly menu system displayed on the in-built

2 line alphanumeric display. Measurements can be read

directly from the display at any time or downloaded

to a computer/printer through the optional RS232 output

at user selectable periodic intervals. The NEP160 will

power up automatically to its last settings whenever

external power is applied making it ideal for logging

applications when using the analogue output or optional

RS232 port.

|

|

| SPECIFICATIONS |

| Range |

0.0 to

20,000NTU (4,000NTU limit on 90° probe) (over

four ranges automatically determined). |

| Display |

2 line, 16-character dot matrix alphanumeric liquid

crystal display. |

| Display language |

English standard, other languages available to

order. |

| Parameters displayed |

- Turbidity (NTU) - default

- Relative Turbidity Reference (NTU)

- Relative Turbifity (Turbidity - Relative Turbidity Reference

NTU)

- Date/Time - default

|

| Reading |

updated every 1 second. |

| Averaging period |

0.5 second or 10 seconds nominal - user

selectable. |

| Range Steps |

- <0.1 to 20NTU

- <1 to 200NTU

- <10 to 2,000NTU

- <100 to 20,000NTU (using 180° probe only)

|

| Resolution |

- 0.02NTU

- 0.1NTU

- 1NTU

- 10NTU

|

| Repeatability |

2% ± digit on all ranges. |

| Data Logging |

User set for one reading every 1 to 90 seconds or

minutes. All readings stored in the Notepad. |

| Notepad |

100 readings each with time and

date. |

| Setup procedures |

| Menu driven, including: |

- Calibration

- Automatic Logging

- Analogue output range selection

- Reference Turbidity value

- Setting date and time.

| |

| Setup memory |

Non-volatile EEPROM. |

| Clock |

Calendar clock displays date and time. Year 2000

compliant. |

| Good Laboratory Practice |

All readings as well as calibration constants are

stored together with the Time and Date and can be recalled at and

time. |

| Analogue Output |

0 - 2 volts full scale corresponding to preset

measurement range. Output impedance 600 ohms nominal. |

| Power |

- Internal: 6V NiMH rechargeable battery.

- External: 12 to 16V dc, 100mA max. incl. NiMH Charge

current.

|

| Power management |

Automatic power down when operating from batteries

after approx. 5 minutes may be selected. Automatic power up when powered

externally.

Low battery indication prior to shut down. |

| Measurement outputs |

Inbuilt LCD, analogue output and optional RS232

port. |

| RS232 Port (optional) |

The optional RS232 port can output readings on

request or at preset intervals of time from 1 to 90 seconds or minutes. The

Notepad memory can also be downloaded on request. 9600 baud rate, 8 bits, no

parity, 1 stop bit, Xon/Xoff protocol. |

| Dimensions |

187mm x 110 mm x 51 mm (display

unit) |

| Weight |

Display unit: 0.5kg

180° probe: 0.2kg with 2m

lead

90° probe: 0.2kg with 2m lead |

| Operating temperature |

0 to 50°C |

| Operating humidity |

0 to 90% RH |

| Storage temperature |

-10 to 60°C |

| Case rating |

IP65 |

|

Turbidity

Meter (WQ770) Turbidity

Meter (WQ770)

|

|

The

Global Turbidity Sensor is a highly accurate submersible

instrument for in-situ environmental or process monitoring.

Applications include; water quality testing and

management, river monitoring, stream measurement, reservoir

water quality testing, groundwater measuring, water

and wastewater treatment, effluent, and industrial control.

Method:

In

accordance with USEPA Method 180.1 for turbidity measurement

the sensor is a 90 degree scatter nephelometer where

a focused beam is directed into the monitored water.

The light beam reflects off particles in the water,

and the resultant light intensity is measured by a photodetector

positioned at 90 degrees to the light beam. The

detected light intensity is directly proportional to

the turbidity of the water. The turbidity sensor

utilizes a second light detector to correct for light

intensity variations, color changes, and minor lens

fouling.

|

|

|

Turbidity

Meter:

The

Global Water Turbidity Meter combines the turbidity

sensor with a handheld meter that has a six digit LED

screen, 4-button control panel, and an internal 9V battery.

The handheld portable water meter can be used

for enivronmental or process sites that do not require

permanent monitoring. The meter will display readings

directly in either nephelometric turbidity units (NTU)

or parts per million (PPM). It also includes an automatic

shutoff feature to conserve battery power.

Range:

Sensor=0-50 NTU and 0-1000 NTU; Meter=0-50 NTU or 0-1000

NTU

Accuracy:

+ 5% of full scale

Meter

Resolution: 12 bit

Method:

Nephelometer with correction

Operating

Voltage: 10-36 VDC @ 40 MS (Sensor); Internal 9VDC battery

(Meter)

Current

Draw: 31 mA plus sensor output (WQ710)

Warm-up

Time: 10 seconds minimum (Sensor)

Operating

Temperature: -40° to +50°C

Materials:

Black anodized aluminum, stainless steel, delrin, Sapphire

optical windows, Polyurethane jacketed cable.

Pressure:

0-50 psi

Light

Source: pulsed LED

Cable

Length: Sensor=25' standard (optional to 500'); Meter=10'

standard (optional to 100')

Size:

Body= 1 1/2"D x 8.5"L Sensor Shield=

1 1/2" x 2" Overall Length: 9"

Weight:

2 lbs.

|

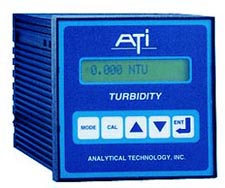

Series

A15/76 Turbidity Monitor Series

A15/76 Turbidity Monitor

|

|

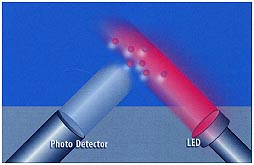

Turbidity

is a general indicator of the optical clarity of water

and is defined as the amount of light scattered from

particles in solution. In practice, a light beam is

directed into a water sample and a photo detector measures

the light scattered at 90° to the incident light

beam. While other scatter angles are possible, the 90°

measurement angle has become the standard for turbidity

measurement in most water systems. It is used as a relative

indicator of the amount of suspended solids in solution

and is measured in virtually all drinking water systems.

It is also used in industrial water treatment systems

as an indicator of product water quality.

|

|

|

Model

A15/79 Turbidity Monitor is designed to meet the needs

of both municipal drinking water systems and industrial

water treatment for reliable, low range turbidity measurement.

Using an infrared light source and a 90° scatter

measurement, the system provides high sensitivity measurement

with unmatched zero stability. Turbidity measurements

down to 0.001 NTU or as high as 4000 NTU can be measured

with the same monitor, eliminating the need for separate

high and low range instruments.

|

|

|

The

turbidity sensor used in the A15/76 is a planer sensor

with the light source and photo detector mounted on

a flat face. Lenses in front of the light source direct

the beam of light at a 45° angle into the sample.

Another lens in front of the photodetector collects

the 90° scattered light and directs it to the detector.

The signal generated by the detector is amplified inside

the sensor for transmission to the display unit. Periodic

pulsing of the light source allows the sensor zero to

be adjusted automatically for improved stability in

low range applications.

Turbidity

sensors are available for measurement in a pressurized

flowcell or for direct submersion in open tanks. The

flowcell is required for very low measurements (0-4

NTU), while the submersion unit may be used for higher

turbidity applications such as wastewater effluent or

raw water.

Air

bubbles are a common problem in many turbidity systems.

ATI's turbidity sensor is designed to operate under

pressure to eliminate the sample degassing that often

causes air bubble errors. Sample pressure in not dropped

until the sample exits the measuring chamber, resulting

in more reliable measurements. The turbidity electronics

unit is a compact panel mount instrument providing an

LCD display of turbidity value, as well as indication

of alarm status and instrument diagnostics. For stand

alone applications, a NEMA 4X wall mount enclosure is

available.

The

monitor provides display of turbidity over a variety

of operating ranges. The minimum display range of 0-4

NTU provides resolution down to 0.001 NTU and is suitable

for almost any final filter monitoring application.

Range of 0-40 or 0-400 NTU are available for raw water

or clarifier effluent monitoring. A0-4000 NTU range

may be used for very high turbidity applications such

as river water monitoring. In addition, the monitor

may be calibrated fur suspended solids measurements,

with range from 0-10 mg/l up to 0-10,000 ml/l.

Standard

turbidity systems provide a variety of outputs. Two

programmable alarms with SPDT alarm relays are included,

as well as an isolated 4-20 mA output. The analog output

may be programmed for full scale outputs as low as 0-0.2

NTU and can inverted if desired. Alarm and output information

can be displayed on the LCD at the push of a button

and the alarm relays can be activated manually for test

purposes when needed.

A15/76

monitors also provide sensor diagnostic functions to

warn of conditions that cause inaccurate or invalid

readings. The sensor is continuously monitored for optical

fouling and will display an alarm message when the sensor

requires cleaning. In addition, the sensor will detect

the lack of water in the flowcell and provide a "dry

cell" when an air interface is detected. These

alarm conditions will cause a third alarm relay to activate,

which can be used to indicate these conditions remotely.

Because

turbidity measurement is often required in wastewater

effluents and other applications where sensor fouling

can be a major problem, ATI offers a special turbidity

unit, the B15/76 system, that uses an "air blast"

sensor cleaning system that automatically cleans the

sensor as often as necessary to maintain reliable measurements.

This system is used only for submersion applications

only, and all air supply components required for the

cleaning process are supplied in the NEMA 4X monitor

package.

| Range |

4/400 NTU (0-4.000, 0-40.00, 0-400.0) |

| 40/4000 NTU (0-40.00, 0-400.0, 0-4000) |

| 9/999 mg/l (or ppm) SiO2 (0-9.999, 0-99.99,

0-999.9) |

| 99/9999 mg/l (or ppm) SiO2 (0-99.99, 0-999.9,

0-9999) |

| Auto ranging over 3 decades of

concentration |

| Accuracy |

+/- 5% of reading or +/- 0.02 NTU, whichever is greater, on 40/400

scale +/- 10% of reading or +/- 2 NTU whichever is greater |

| Linearity |

0.1% of FS |

| Display |

16 character alphanumeric backlit LCD |

| Control Relays |

Two SPDT relay, 5A @ 220 VAC resistive,

programmable deadband and time delay |

| Control Mode |

On/off |

| Alarm Relay |

Independent SPDT relay, 5A @ 220 VAC resistive,

programmable for actuation on high/low values or control failure, also indicates

dry cell condition, fouled sensor or high ambient light |

| Analog Output |

Isolated 4-20 mA, 600 ohm maximum load, programmable output span,

output range user set |

| Temperature |

-20-55°C |

| Humidity |

0-95% RH, non-condensing |

| Power |

110/220 VAC +/- 10%, 50/60 Hz |

| Enclosure |

Panel mount standard, NEMA 4X wall mount optional |

| Sensor Range |

0-4000 NTU |

| Measurement Angle |

90 degree scatter (nephelometric) |

| Response Time |

95% in 10 seconds |

| Sensor Power |

+/- 12 VDC supplied by monitor, preamplifier in sensor

head |

| Sensor Temperature Limit |

0-50°C |

| Sensor Pressure Limit |

0-100 psig |

| Connections |

7 conductor sensor cable, 30 feet standard, 350

feet maximum |

| Sensor Materials |

Delrin body, acrylic optical windows |

| Flowcell Materials |

PVC |

| Flowcell Connections |

4 mm tube fittings (black tubing supplied) |

| Flowcell Pressure |

0-100 psig |

| Flowcell Temperature |

0-60°C |

|

go to product

order go to product

order

For any particular request please

contact:

info@flokal.eu

|